Manufacturing and Production Scheduling

Is there any Advantage to be gained from a Scheduling system?

If the shoe fits...

Modern ERP systems often contain a scheduling component, sometimes companies have simple scheduling tools custom made internally, perhaps as simple as a few Excel-sheets or in the most basic case, a Mr. Jones in the factory-office who's been doing it for eons with a pen and paper. In some cases, these are really all that's needed.

- If, however, you find it hard to keep production flowing, or don't have a clear handle on where every job is in every process and at what stage and status it is, or what the reason is for it not being completed....

- If you find planning around capacity constraints difficult, or quickly reshuffling complicated processes because one job got stuck or a machine had to undergo maintenance and now the entire line has to be moved out....

- If you find that difficult prioritization impacts sales losses or procuring expensive materials ties up your funds while not being converted into goods timeously....

Then, perhaps it is time to get Mr. Jones some help from systems that's been solving these problems for over twenty years.

Understanding the problem

Having all the information about current processes and jobs available, to everyone and in a quick-access manner, is vital to ensure open access and accountability. Many times (if not mostly) people neglect to attend to problems, not because they are lazy or unwilling, but because they didn't know about it in time, or neglected to find out due to difficulty in accessing the information.

If someone can see that a job in their responsibility field needs attention, she or he is likely to attend to it (moreso if everyone can see it). Seeing that there is a problem is of course only half the battle - Seeing it as soon as it happens, and immediately understanding what exactly the problem is will determine the speed with which people can attend to the problem.

Once we understand these implications in our processes, one can easily test by asking:

- Can all people see the entire process?

- Can they do so easily?

- Are problems flagged visibly and instantaneously?

- Are the flagged problems clear and descriptive enough to be easily understood?

- Can jobs be scheduled, moved or re-scheduled with ease or perhaps even automatically?

- Are flow constraints (capacity, maintenance, etc.) clear and easily visible?

- Can managers easily see overviews of achieved yields and times, or highlight candidates for improvement?

These are all very important questions, and if you can't answer "Yes" convincingly to all of them, chances are your people lack the tools to manage the process as efficiently as you would like.

As an aside...

During presentations people often ask: "What do you mean here by 'efficiently'?". It simply means that the efficiency of any process is measured by the amount of resources put into it, vs. the amount of product coming out of it. To improve efficiency you need to either produce more, or use less resources. In manufacturing processes, the "Human" resource (aka: Time spent on it by people) is often a very large (if not the largest) input resource, which means that being able to lower it by a good margin will increase efficiency considerably.

We know what is needed - How does a RIFIN scheduling system solve it?

PlanSys is our flagship system in the manufacturing and production sector, and while it's somewhat involved for a quick discussion (demonstrations often take several hours), we would like to show some highlights covering the points made above:

(Please Note: The following example images are all from actual live systems, so some sensitive values are obscured here, but in the working systems they appear normal.)

Easy access and wide-open visibility

Everyone has easy access to see all schedule information, Job information and processing statistics. Of course stringent access-control allows only specific people to schedule, change or update information with respect to their individual roles, but everyone can see what is going on, nobody is left in the dark.

To maximize this ideal, PlanSys supports:

- Large-format factory displays (LED panels or simply large screens) to make processing statistics and information visible in any open area.

- Multiple User Log-Ins. You may log in from any station on the network without being kicked out from another.

- PlanSys doesn't limit the amount of simultaneous Log-Ins, nor the amount of users (other than when managing high Server-load).

- We will never bill you per user - if it's your system, everyone in your business should be able to use it and see the entire processing schedule. We found one of the most valuable properties of such systems is to provide visibility to all, a property that is directly contradicted with limiting the number of log-ins or users, as is the case in almost every other system out there.

Functional Information - Easy to understand

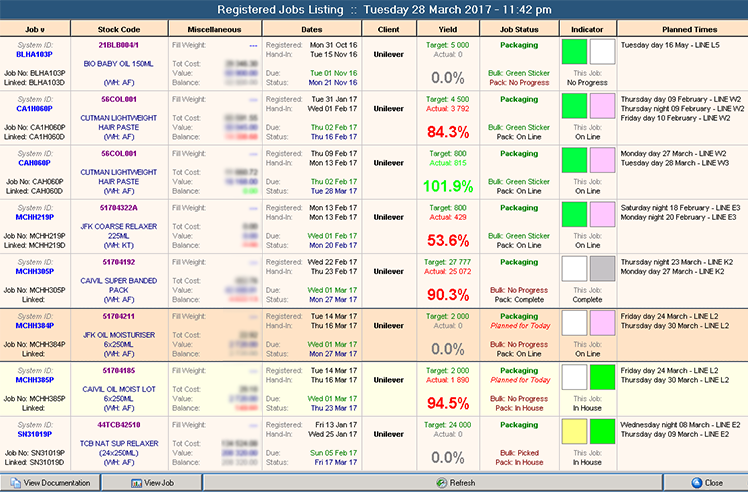

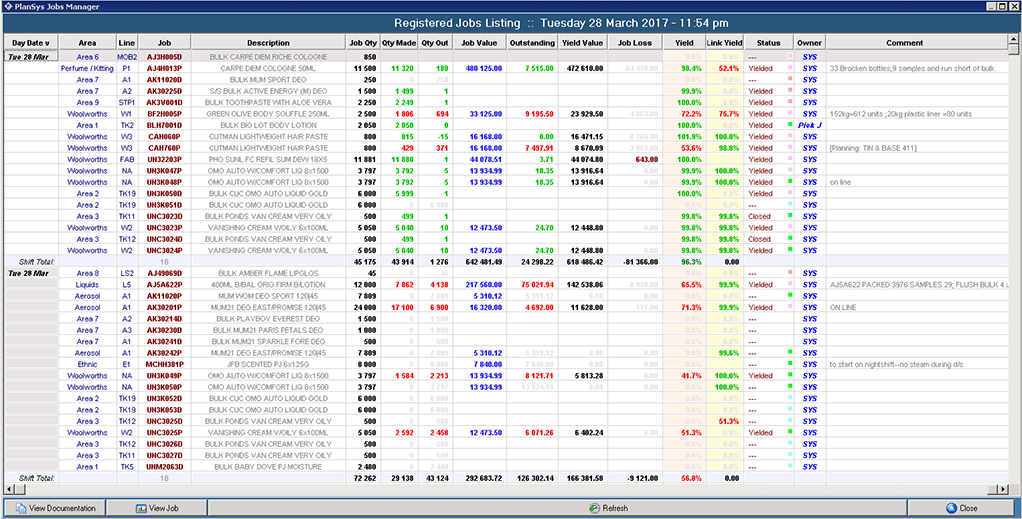

Making information easy to read, finding the right balance between clustering relevant information and highlighting important bits so that anyone can, with a single glance, tell exactly where in the process a job is, how healthy a job is or if something is wrong, what that might be. In this first example, this is a standard job listing with coloured status markers, yield status, notes and relevant indications all in one place and easy to follow:

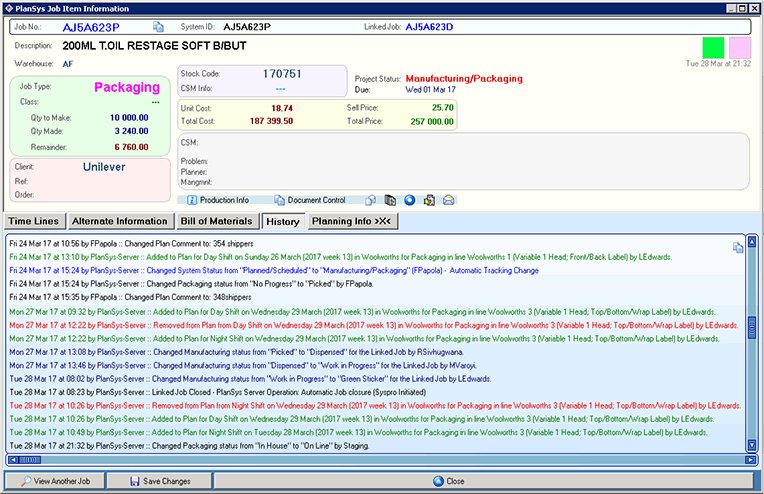

If that information doesn't provide all the answers, simply double-click the item to open up a full view of the details of the job, its scheduling information, progress and most importantly - its full history tracking details:

Understand Capacity Constraints

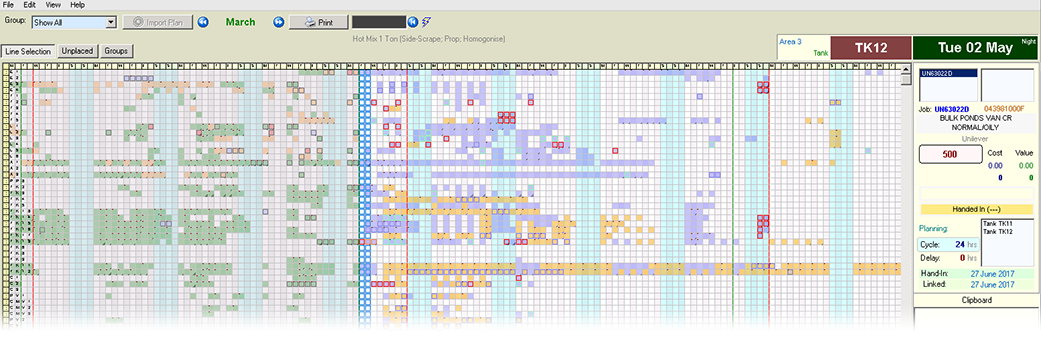

The ability to see an overview of the entire plan for the next few months for all manufacturing/production lines in the factory (or section of it) is paramount to fully determining exposure to and dependence on those capacity factors.

This is a section of a schedule showing which lines run into capacity problems (for example the lines runnig longer than the rest in the bottom half). The bright blue verticle line is "Today", the dim blue vertical columns are week-ends and every red verticle line is a month-end. The small blocks represent usable slots in the production lines (down) and calendar days and shifts (across) with filled-in blocks representing slots where a job is planned (Purple) or should be planned (Yellow):

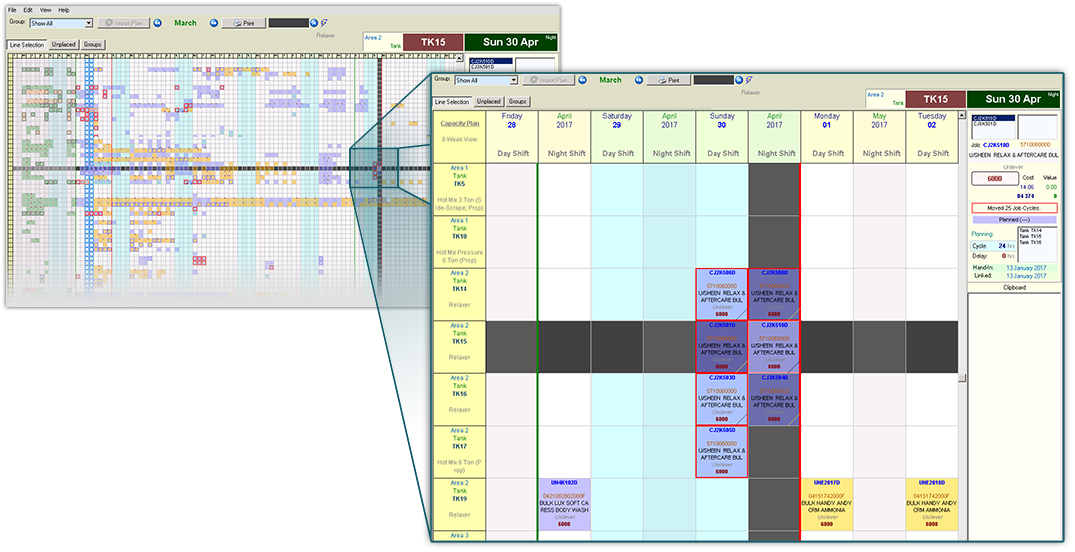

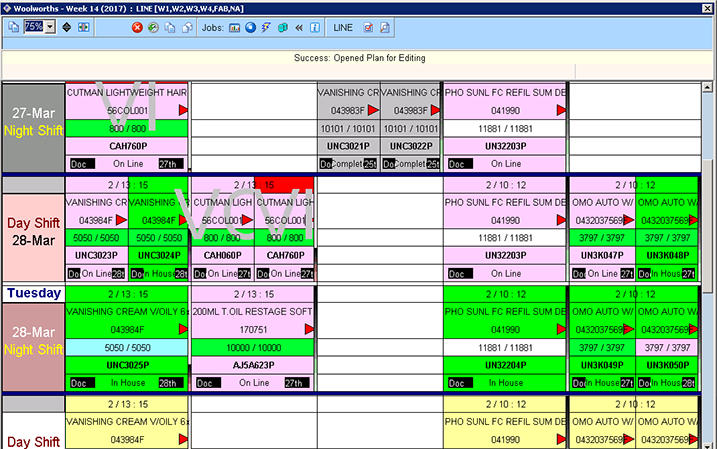

Seeing the overview is very informative, but of course being able to "Zoom" in and reveal the detail is vital to planning how to alleviate the congestion. There are very many small features and information locked into colours and markers, more than can be discussed here, but to a seasoned scheduler or manager using this system, it quickly details a wealth of information that allow faster and more-informed planning decisions:

Easy Scheduling functions

Schedules can be viewed and edited per area or per line with easy drag-drop interfaces and a plethora of information packed into the colours, markers and writing - again this provides a very fast reference, and anyone using it for a while is able to see with a quick glance exactly what the statuses of jobs in an area are or any problems being experienced by those jobs:

Note: The colours and markers both are fully configurable. At this factory, the "VC" marker indicates a client-validation batch, Yellow jobs are being picked, green jobs are ready to go and pink-ish jobs are being made on the line, and that red block is a problematic Job. Gray jobs are done. Different zoom levels will clear up detail and relax congestion of the visuals, but it allows quick transformation between "Overview" and "Detail" style viewing.

Full information on the production line or Job detail is, as always, just a click away via context menus or quick-access buttons.

The Plan may also be printed in part or in it's entirety, making it easy to share with factory floor personnel that might not have access to computer terminals, or to discuss a specific problem area in a meeting.

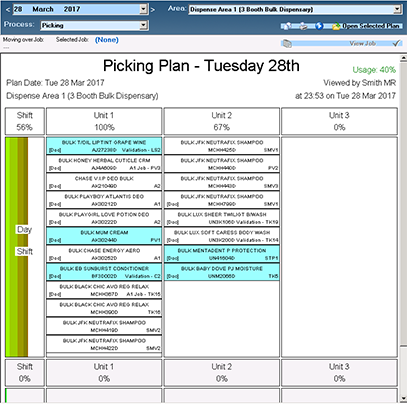

Different plan-views exist to make it easier for other relevant users to achieve their tasks. This next view is a custom-designed view of the plan specifically to inform the Ware-house Pickers on which Jobs to pick for next:

Management Overview of Progress, Yields and Problems

It's all good to be able to schedule something to happen, but did it happen? Did it happen correctly and fully? Was there any problem, and if so, what was it?

These are the questions that usually haunt operations managers/directors, who in turn place pressure on factory managers, whom often ends up spending more time on collecting data to answer with, than managing the actual processes. With PlanSys it's made easy in a simple set of views that can be tailored and filtered to see specifics or provide an overview. This example shows two shifts for a single factory with all the relevant information and totals:

About PlanSys

Some of the RIFIN people have been studying and improving (or trying to!) manufacturing and production scheduling for more than 20 years (since the late 90's). PlanSys (in stand-alone system form) started life in early 2003 at a client who, after a very successful implementation of a different system, asked us to assist with the nightmare that was Scheduling. We learned as much from them as they did from us, they were experts at difficult scheduling, but had to do so on archaic systems.

A long-term evolution began of achieving goals, then refining and re-thinking scheduling behaviour, from all of the product's, the factory's and the human's perspectives. Seemless integration with main-stream ERP systems and later with on-line functionality became design goals. More clients with similar needs came on-board, and later clients with widely different needs. The system was re-designed from the ground up in 2009 to accommodate all these ideals.

Seven years later, in 2016 another overhaul started, now with the newest available technologies, the cumulative experience of the RIFIN systems architects, and clients old and new, PlanSys has evolved to become possibly the best scheduling system available anywhere - at least as far as manufacturing and production-line goods factories are concerned.

Let us know (by clicking the link below) if you think there is room for improvement with your Scheduling and would like to see what the future could be.